If you’re in the exterior cleaning business, from residential home washing to commercial surface cleaning, a soft wash system is essential equipment. Unlike traditional pressure washers, soft wash systems rely on low pressure and specialized solutions to safely remove algae, mold, mildew, and stains without damaging delicate surfaces. In this guide, we’ll walk through how to build a reliable, high-performing soft wash system that works for your needs.

What Is a Soft Wash System and Why You Need One

A soft wash system is a cleaning setup that delivers cleaning solutions at low pressure to break down organic growth and contaminants instead of blasting them away with force. This method is ideal for:

- Siding and roofs

- Decks and fences

- Outdoor furniture

- Gutters and trim

By using carefully blended detergents and low PSI output, soft washing prevents surface damage and improves long-term cleanliness.

Step 1: Choose a Reliable Frame or Trailer

Start with a sturdy base for your system. Options include:

- Trailer Frame: Great for mobile operations and hauling larger tanks.

- Skid Mount: Perfect for trucks, trailers, or flatbeds.

- Portable Cart: Ideal for smaller jobs or tight spaces.

Make sure your chosen frame is rated for the weight of water, chemicals, pumps, and tanks you plan to install.

Step 2: Select the Correct Tanks

Your soft wash system needs two tanks:

Water Tank

- Usually 50-100+ gallons depending on job size.

- Choose food-grade, UV-resistant tanks for durability.

Chemical Tank

- Smaller (10-20 gallons) for concentrated detergents.

- Secure with proper mounting and venting.

Tip: Clearly label tanks to prevent mixing mistakes on job sites.

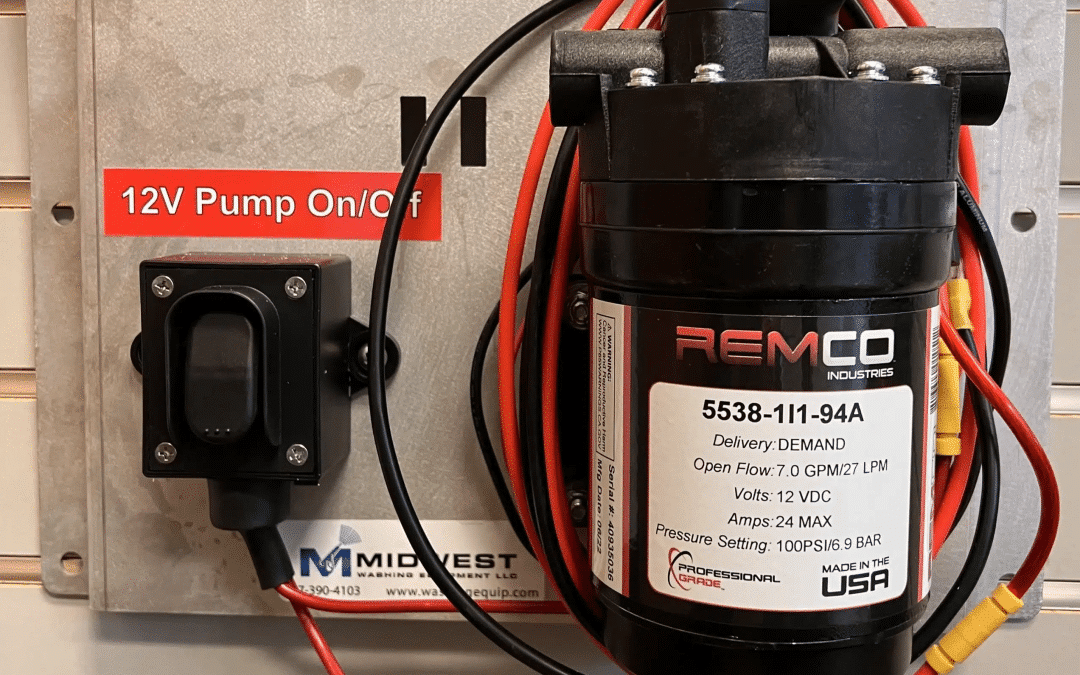

Step 3: Pick the Right Pump

The heart of your soft wash system is a chemical injection pump capable of low-pressure delivery. Look for:

- Adjustable flow rates

- Smooth, consistent output below 500 PSI

- Chemical-resistant seals and components

Popular choices include diaphragm pumps and soft wash-specific pumps designed for detergent dosing.

Step 4: Add Valves, Hoses, and Connectors

Proper plumbing ensures your system runs smoothly:

- Chemical Injector or Proportioner: Regulates detergent mix into the water stream.

- High-Quality Hoses: Use chemical-rated hoses to resist corrosion and breakdown.

- Ball Valves & Quick Connects: Enable fast change-outs on hoses and nozzles.

Installing check valves and strainer filters helps protect the pump and prevents clogs.

Step 5: Choose Nozzles and Spray Equipment

Soft wash nozzles are designed to produce wide, gentle spray patterns. Typical choices include:

- Low-pressure fan nozzles

- Adjustable spray guns

- Long-reach wands for roofing and siding

Color-coded spray tips help ensure consistent application rates in the field.

Step 6: Mix and Deliver Detergents Safely

Soft wash relies on the right chemical blend. Common solutions include:

- Sodium hypochlorite (bleach) for mold/mildew

- Surfactants to improve adhesion

- Water conditioners to stabilize solutions

Safety first: Always use proper PPE (gloves, goggles, masks) when handling concentrated chemicals. Follow manufacturer instructions and local regulations.

Step 7: Test Your System Before First Use

Before heading to a job site:

- Run water through the system to remove air.

- Check for leaks and adjust flow rates.

- Test chemical injection ratios for proper cleaning power.

This step ensures consistent performance and prevents on-site delays.

Maintenance and Troubleshooting Tips

To keep your soft wash system working reliably:

- Rinse tanks and lines after every use.

- Inspect pump seals and diaphragms regularly.

- Store equipment out of direct sunlight.

- Replace worn hoses or fittings promptly.

Regular care increases lifespan and keeps cleaning results strong.

Get Expert Support from Aqua-Engineers

Building your own soft wash system doesn’t have to be complicated. From choosing components to troubleshooting performance, Aqua-Engineers has the parts, expertise, and support you need. Whether you’re upgrading a current setup or starting from scratch, we’re here to help you build a system that delivers consistent, professional results.

Contact Aqua-Engineers today to discuss custom builds, replacement parts, and technical guidance.